Browsing through Weavolution last week, I came across a Weave-Along on the Rigid Heddle list. See post #28 (sorry, can’t figure out how to link to a specific post). I was obsessed with trying this out.

So, yesterday, I measured out a 70″ warp (enough for 2 small table toppers) and went to town. It took me 4+ hours to warp this darn thing and tie on two continuous heddle string/bar (for shafts 2 & 3). Then an hour to heave the first 2″. 5 hours into this thing and I have something that I wouldn’t give to my cat as a cat bed.

Problems? Tension on the warp, to name one. But more importantly, threads 2 & 3 share the slot in the rigid heddle. These get completely muddled up and I can’t get a clean shed on 2 & 3. I spend 2-4 minutes on each shed, trying to clear it. A girl can go grey weaving this. Oh, wait, I already am turning grey. Never mind.

Here are a series of pictures to show Heather that it is possible to do a diamond twill on a Cricket. If one had the perseverance, that is.

Tie up in progress. 1 thread through the hole; 2 threads through the slot.

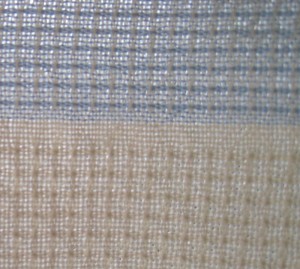

Wonky tension and 1 threading error aside, here's what it looks like on the loom. You can see 3/4 of a diamond here.

The back shows the diamond more dramatically.

Yup. I’ve cut the puppy off. I was going to put it onto the Gilmore, but I’ve changed my mind. It’s not worth the < $10 in yarn to try and salvage this. I’ll re-purpose the yarn for tying up warp chains or something.

The yarn? Paton Grace 100% mercerized cotton from Michael’s. It’s approximately the same size as 3/2 cotton.